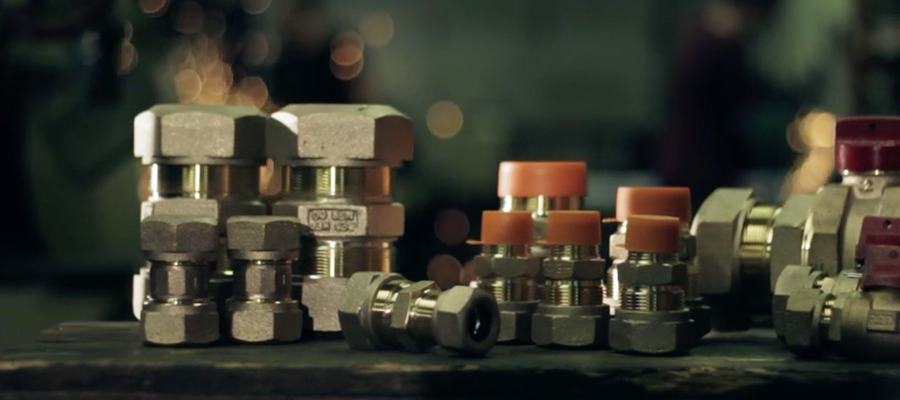

When you're in the water utility industry, you can see all manner of fittings to adapt older pipe to newer systems. Threaded, compression and flared fittings are all common connections to run across. But how do you connect pipes to these fittings to get a proper fit that will stand up well to pressure and time? Here's a quick look at the most common fitting types and how to ensure you get a proper seal.

Threaded

Threaded connections are either male, with threads on the outside, or female, with threads on the inside. They work well with a wide range of pipe materials, providing a strong connection held in place mechanically, with the threads preventing the pipe from slipping out of place. Teflon tape or pipe joint compound are applied to the male section of the assembly, then the female end is threaded on and tightened. The tape or compound ensure a tight seal while protecting the connection against internal corrosion that could lead to premature failure or being corroded together, making it very difficult to change out in the future.

Compression

Compression fittings are used with copper and plastic pipe materials. They use a ferrule, a small ring of brass or copper that is squeezed between two parts of the fitting until it deforms and fits tightly against the pipe, holding it in place. To install, the nut is placed on the pipe first, followed by the ferrule. The fitting itself is placed at the end of the pipe, then the nut is tightened against it. This causes the ferrule to deform. If you're using plastic pipe, such as PEX, place the brass insert inside the pipe to ensure that it's the ferrule that compresses, not the pipe itself.

Flare

Flared fittings are used in both gas and water lines. They're created by flaring the end of a run of soft copper pipe or tubing, which is then secured between the fitting and the nut. Start by placing your nut on the copper line to be flared, then place your flaring tool on the pipe, with about 1/16" of pipe extending past the tool. Flare the pipe per your tool's instructions, remove the tool and attach the fitting, tightening the nut to capture the flared pipe between the nut and the fitting.

By taking the time to get a solid connection into the supply line, you can ensure that you're not losing water and that you can avoid having external contaminants enter the water supply. Red Hed's lead flange adapters provide you with an easy solution to switch from one type of pipe to another without having to stack multiple fittings to make the switch, saving your crew time on the job and space in tight quarters. Our 100% lead free fittings provide your customers with peace of mind that they're getting the best possible water quality for themselves and their families. If you need any help finding the right adapters for your water utility, it's easy to contact Team Red Hed for the answers you need.