When your tap machine stops working, your crew is faced with a problem. With the average age of equipment in the waterworks industry at three decades or more, it's no surprise that your machinery has issues. You have options beyond scrapping old machinery or expensive replacements. We'll give you several options to get your tap machine back to work. Our full machine shop makes it possible for us to do anything from small repairs to complete rebuilds.

B-TOO

Standard Tap Machines

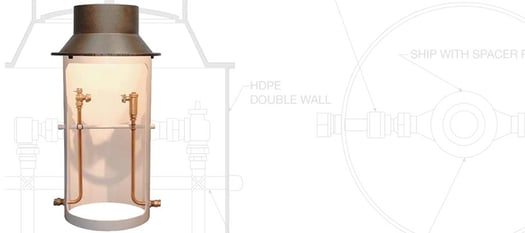

Among the standard direct-tap machines we rebuild are the Romac B-Too, Mueller B101 and Reed TM1100. We keep parts on hand for the Mueller machines due to their prevalence in the industry, are able to quickly order in parts for the less-common Romac machinery and Reed parts are available a day or two away.

But what about older machinery? Sometimes you need custom parts for that specific machine. Without full-service shop, making bushings and spacers are a simple task for us to manage for you in-house, tapping our extensive network of foundries and metal suppliers to get the job done right. Once repairs are completed, our service techs operate and test the machine to ensure it's operating properly.

Large Tap Machines

What about your larger tap machines? We're able to handle repairs to the Mueller CL12, AP Smith, Romac Tapmate and other large machines on a per-machine basis. Like with direct tap machines, we can get parts quickly from Romac, but for Mueller or AP Smith machinery, it's not uncommon to hear about part backorders of six months or more.

For that reason and to provide additional service to our customers, we can create the necessary parts in our metal shop to your exact specifications. We take care of locating and purchasing the aluminum, bronze or cast iron casting, then machine it to the right size, shape and thread specification to make it work.

The Process

Generally speaking, we receive a machine and when our foreman is available, he evaluates it to determine exactly what is wrong and develops a part list, time estimate and quote proposal. Generally speaking, typical jobs will take about 2-3 weeks, though they can go more quickly depending on the issues.

We generally recommend that you plan a minimum of one month for large tap machines, as they're more difficult to diagnose and get parts for. Making custom parts requires a three-week lead time to allow for having a casting poured or to buy slugs or plates of metal, then cut and machine them exactly.

By understanding your options, you can ensure that you'll be able to make smart decisions about what you need to do with your tapping machine, whether it's repair, refurbishment or replacement. But what if you're on the fence between a couple different decisions and aren't quite sure which way you should go? Team Red Hed can help. Our team of experienced associates can help you through the process so that you can make the right decision for your water utility. Please feel free to reach out today to learn more.